Method 1 -

January

21, 2005

The Atlas

Press Co. 10 inch lathe that I purchased for my son had a form of

metallurgical cancer in the Zamak aluminum-zinc alloy gears.

Several teeth fell right out of the main bull gear on the headstock,

and closer examination revealed swelling and cracks everywhere on the

gear. So I had to machine a new one to make the lathe

functional. Even though Atlas's owner, Clausing, is extremely

cooperative and

helpful, a new wrought aluminum gear from them was way outside my

budget.

The Atlas

Press Co. 10 inch lathe that I purchased for my son had a form of

metallurgical cancer in the Zamak aluminum-zinc alloy gears.

Several teeth fell right out of the main bull gear on the headstock,

and closer examination revealed swelling and cracks everywhere on the

gear. So I had to machine a new one to make the lathe

functional. Even though Atlas's owner, Clausing, is extremely

cooperative and

helpful, a new wrought aluminum gear from them was way outside my

budget.

Problem

was, the gear was so large that I could not swing it on the

Atlas index head and still get a gear cutter over the top. So the

gear had to be machined horizontally on the Atlas's meager rotary

table, which has no indexing capability whatsoever. My solution

is shown at left. The bad gear is mounted flat on the rotary

table. Above it is the new gear, with about three-quarters of its

teeth already cut. In the foreground is the Atlas lathe's second

back gear, removed from the gear cluster for the time being. The

index pawl is at the far right. The pawl engages the teeth of the

intact second back gear, and that gear's teeth average out the errors

and bridge over the gaps in the defunct bull gear. The gear was about

three-quarters finished when I took the picture. |

The new gear

teeth are shown above the bad bull gear's teeth at left. I

offhand ground the fly cutter, so these are not the quietest teeth on

the planet. But they work great. After a little running in,

the meshing quieted down. I did take a lot of trouble to make the

fit of the bore of the gear blank very close to the seat on the outside

of the spindle and to mount the blank concentrically on the rotary

table, and that worked out well.

The new gear

teeth are shown above the bad bull gear's teeth at left. I

offhand ground the fly cutter, so these are not the quietest teeth on

the planet. But they work great. After a little running in,

the meshing quieted down. I did take a lot of trouble to make the

fit of the bore of the gear blank very close to the seat on the outside

of the spindle and to mount the blank concentrically on the rotary

table, and that worked out well.

The idler gear rotates on a shaft mounted on the I-beam; I left it free

to rotate, held only by the index pawl. Of course, once I had

indexed to each new tooth, I took up the slack and then tightened the

clamps that kept the rotary table and the gears bolted to it from

rotating. So everything was nice and tight when I started each

cut. There's lots of impacting from that fly cutter, seen at top

left of the image at left. Note

that I fed the knee upwards to get a smooth motion without the force of

the cutter tending to lift the

knee or saddle.

The principal limitation of this technique is the reach of the fly

cutter. It would be more rigid to use the Atlas's overarm to

support the outboard end of the flycutter. One might make a gear

a foot across; I haven't checked what the exact limit might be. |

|

Method

2 - June 13, 2013

Method 1 was necessitated by that cancerous

bull gear. The present Method 2 came out of my decision to complete the

set of metric change gears that I started about 25 years ago. I started

with the composite 127/100 gear set from South Bend lathe that can be

seen at

the bottom of the stack in the image at left. The large aluminum plate

near the top of the stack is the intended lead screw gear, which is to

be a

copy of the 100-tooth gear in the 127/100 composite, but with a 0.5625

(i.e., 9/16) inch bore and 0.125 (i.e., 1/8) inch keyway. You may also

notice that I've graduated to a real gearcutter, which in turn

necessitated making the 0.875 (i.e., 7/8) inch arbor seen at left.

Method 1 was necessitated by that cancerous

bull gear. The present Method 2 came out of my decision to complete the

set of metric change gears that I started about 25 years ago. I started

with the composite 127/100 gear set from South Bend lathe that can be

seen at

the bottom of the stack in the image at left. The large aluminum plate

near the top of the stack is the intended lead screw gear, which is to

be a

copy of the 100-tooth gear in the 127/100 composite, but with a 0.5625

(i.e., 9/16) inch bore and 0.125 (i.e., 1/8) inch keyway. You may also

notice that I've graduated to a real gearcutter, which in turn

necessitated making the 0.875 (i.e., 7/8) inch arbor seen at left.

|

Another task

was making the four smaller gears (18, 20, 22 & 26 teeth) that are

also needed to cover the

expected range of metric thread pitches. I made the first of these with

the same flycutter (albeit ground to match the smaller gears in the

lathe's normal English change gears, which of course are all

interchangeable with the same 18 diametral pitch, 14-1/2 degree

pressure angle as the metric change gears). Shown at left is the Atlas

indexing head and the master gear (twice as many teeth, hence skipping

every other tooth with the index pin). The others I made with

gearcutters.

Another task

was making the four smaller gears (18, 20, 22 & 26 teeth) that are

also needed to cover the

expected range of metric thread pitches. I made the first of these with

the same flycutter (albeit ground to match the smaller gears in the

lathe's normal English change gears, which of course are all

interchangeable with the same 18 diametral pitch, 14-1/2 degree

pressure angle as the metric change gears). Shown at left is the Atlas

indexing head and the master gear (twice as many teeth, hence skipping

every other tooth with the index pin). The others I made with

gearcutters.

|

|

To make the 7/8 inch arbor, I hunted around my basement and found a

likely looking piece of ferrous material, but on the first pass it

became clear that I was machining a piece

of

wrought iron. Except for needing to sharpen the high speed steel

cutting tool frequently, it was easy to work accurately; note the pile

of short, curly chips. Not shown is the splinter of slag that I got

while caressing my fine work ...

To make the 7/8 inch arbor, I hunted around my basement and found a

likely looking piece of ferrous material, but on the first pass it

became clear that I was machining a piece

of

wrought iron. Except for needing to sharpen the high speed steel

cutting tool frequently, it was easy to work accurately; note the pile

of short, curly chips. Not shown is the splinter of slag that I got

while caressing my fine work ...

The images at right show the chip pile in greater detail

as well as my process for making the 5/8 inch clamping nut for the

arbor.

|

|

|

|

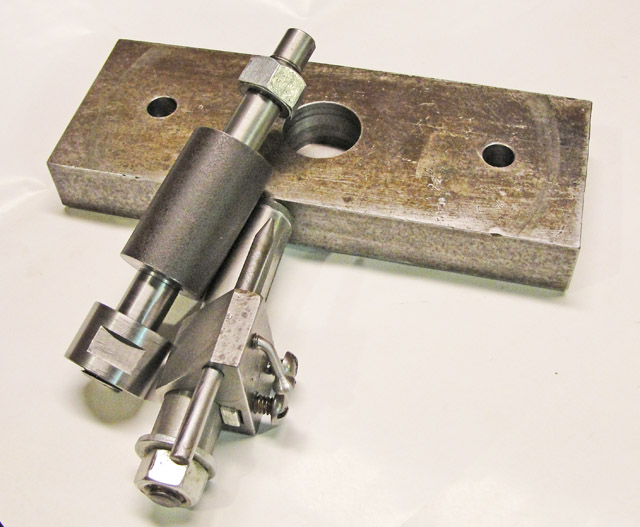

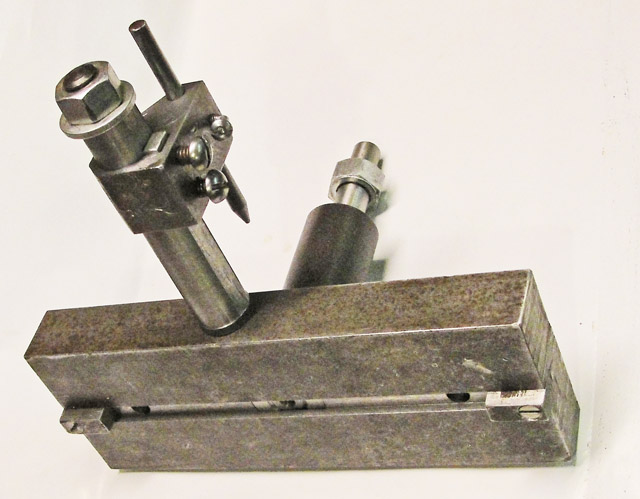

The series of images

below show the completed vertical arbor, which consists of two main

pieces: A base, made from a piece of 1x3x8 inch cold rolled steel,

which only needed a receptacle bored out to a close fit to the lower

clamping nut of the gear carrier, a keyway to fit the Atlas main table,

holes for the clamping screws and tee nuts that hold the base down, and

an adjustable index pin to accommodate the master gear. The adjustable

index pin is held by a sliding member that is keyed to the tubular

support arm. When I cut the present 100-tooth gear, I moved one

of the spacer gears underneath the blank, the better to support it

against the downward force exerted by the gear cutter. Making

non-cluster gears will necessitate making a new gear carrier to fit the

9/16 inch bore of separate change gears.

Here's the setup, shown towards the end of

the three-hour tooth-forming process. The two strap clamps are keeping

the gear carrier and master gear from rotating and take the load off

the index pin. There was some vibration of the gear carrier because of

deflection of the 100-tooth master gear (second from the bottom) whose

web is rather thin. Next time I will wedge spacers between the two

gears or separate them entirely and use a flat-plate spacer on top of

the master gear. The cutter passed through the first tooth gap cleanly

after the gear was finished, proving that nothing had slipped. Here's the setup, shown towards the end of

the three-hour tooth-forming process. The two strap clamps are keeping

the gear carrier and master gear from rotating and take the load off

the index pin. There was some vibration of the gear carrier because of

deflection of the 100-tooth master gear (second from the bottom) whose

web is rather thin. Next time I will wedge spacers between the two

gears or separate them entirely and use a flat-plate spacer on top of

the master gear. The cutter passed through the first tooth gap cleanly

after the gear was finished, proving that nothing had slipped.

In practice the 127 tooth member of the 127/100 compound

gear is driven by the lathe's stud gear (which rotates at the same rate

as the lathe spindle), and the 100 tooth member of the 127/100 compound

gear in turn drives the 0.125 inch pitch lead screw, either through a

72 tooth idler for the 6.00 mm through 2.00 mm thread pitches, directly

for the 1.75 mm through 0.40 mm pitches, or with a 4:1 reduction by the

72/18 tooth compound gear that is part of the standard English thread

change gear set. The 100 tooth change gear that I just made is used

alternately with the 80 tooth change gear from the English thread

change gear set on the English lead screw.

I did not make a proper metric change gear setup for the

image at right, which was intended simply to demonstrate to myself that

the 100 tooth gear meshes correctly with the other 18 DP, 14-1/2 PA

gears without excessive runout. OK !!

|

|

Note: Most of the above images can be

viewed in greater detail by right-clicking with the mouse and selecting

"view image."

|

The Atlas

Press Co. 10 inch lathe that I purchased for my son had a form of

metallurgical cancer in the Zamak aluminum-zinc alloy gears.

Several teeth fell right out of the main bull gear on the headstock,

and closer examination revealed swelling and cracks everywhere on the

gear. So I had to machine a new one to make the lathe

functional. Even though Atlas's owner, Clausing, is extremely

cooperative and

helpful, a new wrought aluminum gear from them was way outside my

budget.

The Atlas

Press Co. 10 inch lathe that I purchased for my son had a form of

metallurgical cancer in the Zamak aluminum-zinc alloy gears.

Several teeth fell right out of the main bull gear on the headstock,

and closer examination revealed swelling and cracks everywhere on the

gear. So I had to machine a new one to make the lathe

functional. Even though Atlas's owner, Clausing, is extremely

cooperative and

helpful, a new wrought aluminum gear from them was way outside my

budget. The new gear

teeth are shown above the bad bull gear's teeth at left. I

offhand ground the fly cutter, so these are not the quietest teeth on

the planet. But they work great. After a little running in,

the meshing quieted down. I did take a lot of trouble to make the

fit of the bore of the gear blank very close to the seat on the outside

of the spindle and to mount the blank concentrically on the rotary

table, and that worked out well.

The new gear

teeth are shown above the bad bull gear's teeth at left. I

offhand ground the fly cutter, so these are not the quietest teeth on

the planet. But they work great. After a little running in,

the meshing quieted down. I did take a lot of trouble to make the

fit of the bore of the gear blank very close to the seat on the outside

of the spindle and to mount the blank concentrically on the rotary

table, and that worked out well. Method 1 was necessitated by that cancerous

bull gear. The present Method 2 came out of my decision to complete the

set of metric change gears that I started about 25 years ago. I started

with the composite 127/100 gear set from South Bend lathe that can be

seen at

the bottom of the stack in the image at left. The large aluminum plate

near the top of the stack is the intended lead screw gear, which is to

be a

copy of the 100-tooth gear in the 127/100 composite, but with a 0.5625

(i.e., 9/16) inch bore and 0.125 (i.e., 1/8) inch keyway. You may also

notice that I've graduated to a real gearcutter, which in turn

necessitated making the 0.875 (i.e., 7/8) inch arbor seen at left.

Method 1 was necessitated by that cancerous

bull gear. The present Method 2 came out of my decision to complete the

set of metric change gears that I started about 25 years ago. I started

with the composite 127/100 gear set from South Bend lathe that can be

seen at

the bottom of the stack in the image at left. The large aluminum plate

near the top of the stack is the intended lead screw gear, which is to

be a

copy of the 100-tooth gear in the 127/100 composite, but with a 0.5625

(i.e., 9/16) inch bore and 0.125 (i.e., 1/8) inch keyway. You may also

notice that I've graduated to a real gearcutter, which in turn

necessitated making the 0.875 (i.e., 7/8) inch arbor seen at left. Another task

was making the four smaller gears (18, 20, 22 & 26 teeth) that are

also needed to cover the

expected range of metric thread pitches. I made the first of these with

the same flycutter (albeit ground to match the smaller gears in the

lathe's normal English change gears, which of course are all

interchangeable with the same 18 diametral pitch, 14-1/2 degree

pressure angle as the metric change gears). Shown at left is the Atlas

indexing head and the master gear (twice as many teeth, hence skipping

every other tooth with the index pin). The others I made with

gearcutters.

Another task

was making the four smaller gears (18, 20, 22 & 26 teeth) that are

also needed to cover the

expected range of metric thread pitches. I made the first of these with

the same flycutter (albeit ground to match the smaller gears in the

lathe's normal English change gears, which of course are all

interchangeable with the same 18 diametral pitch, 14-1/2 degree

pressure angle as the metric change gears). Shown at left is the Atlas

indexing head and the master gear (twice as many teeth, hence skipping

every other tooth with the index pin). The others I made with

gearcutters. To make the 7/8 inch arbor, I hunted around my basement and found a

likely looking piece of ferrous material, but on the first pass it

became clear that I was machining a

To make the 7/8 inch arbor, I hunted around my basement and found a

likely looking piece of ferrous material, but on the first pass it

became clear that I was machining a

Here's the setup, shown towards the end of

the three-hour tooth-forming process. The two strap clamps are keeping

the gear carrier and master gear from rotating and take the load off

the index pin. There was some vibration of the gear carrier because of

deflection of the 100-tooth master gear (second from the bottom) whose

web is rather thin. Next time I will wedge spacers between the two

gears or separate them entirely and use a flat-plate spacer on top of

the master gear. The cutter passed through the first tooth gap cleanly

after the gear was finished, proving that nothing had slipped.

Here's the setup, shown towards the end of

the three-hour tooth-forming process. The two strap clamps are keeping

the gear carrier and master gear from rotating and take the load off

the index pin. There was some vibration of the gear carrier because of

deflection of the 100-tooth master gear (second from the bottom) whose

web is rather thin. Next time I will wedge spacers between the two

gears or separate them entirely and use a flat-plate spacer on top of

the master gear. The cutter passed through the first tooth gap cleanly

after the gear was finished, proving that nothing had slipped.