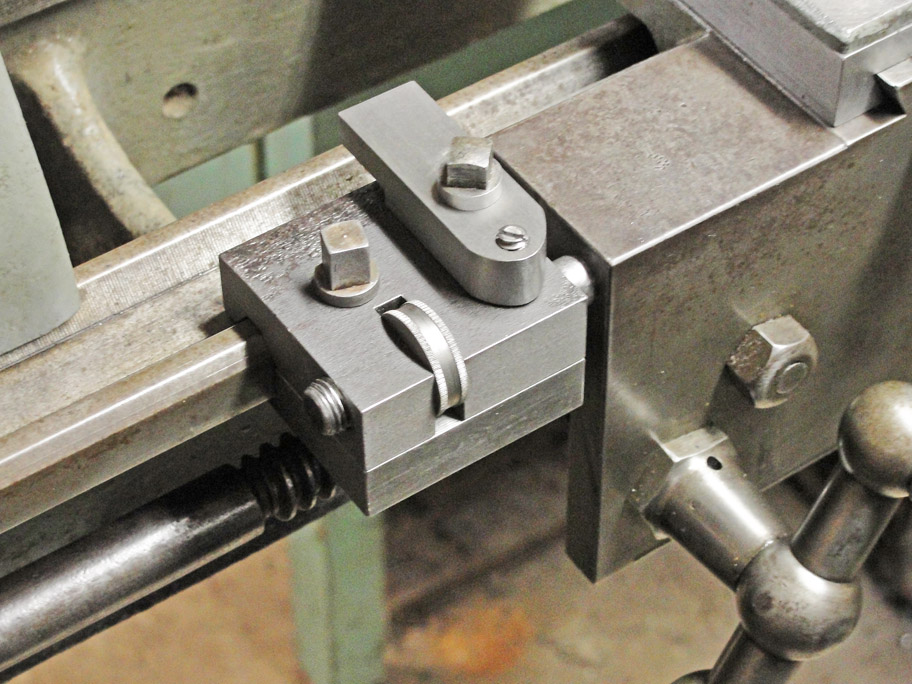

The threading stop enables one to repeat the

radial position of the threading tool after returning the saddle to the

starting position. The advancement of the cutting tool is done

with the top slide of the compound set at 29 degrees to the work axis.

|

My threading stop was patterned after the South

Bend lathe's device, except that it sits in front of the crossfeed

slide instead of holding it back from the handwheel side. This avoided

my having to find a place for the screw otherwise required.

|

The dovetails of the saddle are 3/8 inch high,

so a pair of 3/8 inch steel dowel pins facilitates making the

measurements of the fit of the male and female dovetails. The inside

measurement (below) omits two diameters of those dowels.

|

The outiside measurement (below) incudes two

diameters of the dowels. Once these diameters are accounted for, the

inside & outside measurements compare directly without any sines

and

cosines.

|

The numbering subpress is shown at left. First,

I used the indexing centers of the Atlas lathe to mark five radial

nicks in the side of the micrometer wheel, and then I used the vise

to hold the subpress while I made the number markings with 1/16 inch

stamps in my No.2 arbor press.

The numbering subpress is shown at left. First,

I used the indexing centers of the Atlas lathe to mark five radial

nicks in the side of the micrometer wheel, and then I used the vise

to hold the subpress while I made the number markings with 1/16 inch

stamps in my No.2 arbor press.  I

"thoughtfully" counterbored the hole for the

carriage stop's clamp screw, but then I couldn't find a suitable spring

to fit in the small annular space between the screw and the hole.

I

"thoughtfully" counterbored the hole for the

carriage stop's clamp screw, but then I couldn't find a suitable spring

to fit in the small annular space between the screw and the hole.